Adapting Viral Safety Assurance Strategies to Continuous Processing of Biological Products

CDER researchers are working to ensure the safety of therapeutic proteins produced by continuous manufacturing.

Shifting Therapeutic Protein Drug Substance Manufacturing Paradigms

The manufacture of therapeutic proteins often consists of expression of the target protein in an engineered cell line followed by a series of purification steps to remove product- and process-related impurities. For therapeutic proteins expressed in mammalian cell lines, the host cells may contain multiple copies of endogenous retrovirus-like sequences that produce retrovirus-like particles (RVLPs) in addition to the target protein. Although RVLPs are generally thought to be defective, some have been shown to infect non-rodent cell lines. Exogenous viral contamination, from raw materials or personnel, may also occur. Therefore, guidance document ICH Q5A takes a three-pronged approach to address viral safety risks: i) starting material testing (i.e., cell bank testing), ii) raw materials and intermediates testing, and iii) viral clearance testing during the purification process. The purification process includes both non-dedicated (i.e., chromatography) and dedicated virus clearance steps (i.e., chemical inactivation and virus filtration) to effectively clear RVLPs (and any possible viral contaminants) from the final drug product. For the past two decades, CDER has led a collaborative research program to better understand how to remove viral particles during the manufacture of protein biologics using chromatographic, chemical inactivation, and filtration steps. This research has supported the development of regulatory policies and recommended practices, standards, and industry-wide technical reports (ICH Q5A rev. 1, PDA TR 41 and 47 2, ASTM E2888-12 and WK65429 3. However, recently there has been a push from batch manufacturing processes toward continuous manufacturing (CM) paradigms.

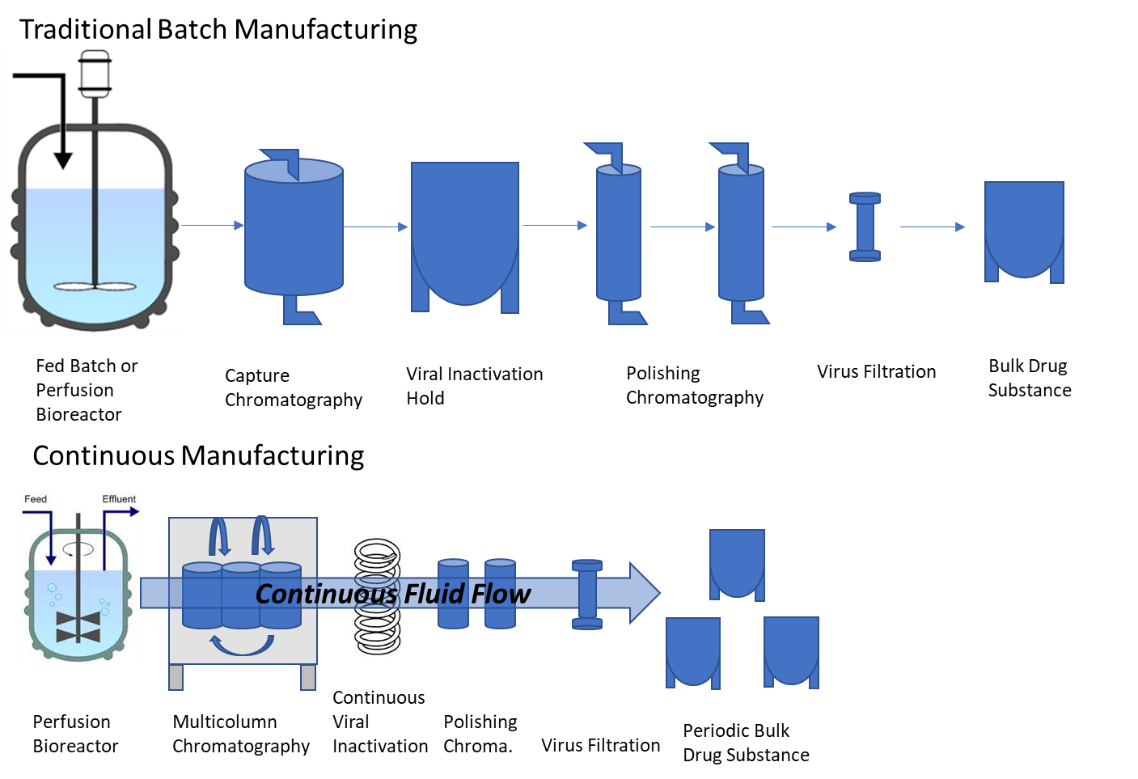

CM is the next step in the evolution of therapeutic protein manufacturing and promises to increase efficiency through the immediate capture and purification of the target protein as it is produced in the bioreactor (Figure 1). This integration of production and purification allows for shorter processing times, reduced manual intervention, and a reduction in facility size through the use of smaller tanks, bioreactors, and columns. Despite these advantages, the individual unit operations as well as their connecting interfaces are different from those for batch mode processing, creating unique challenges in how viral safety and other risk-based approaches will be assured. CDER researchers collaborate with external stakeholders to investigate these unique challenges and their impact on viral safety.

Figure 1. Comparison of batch manufacturing to continuous manufacturing. Batch manufacturing may use large bioreactors (>12kL), the contents of which are harvested as one pool. Purification thus requires the use of large-diameter columns with elution pooling steps between each unit operation to homogenize and buffer-adjust the product fluid stream prior to the next step. Due to hold steps, bulk drug substance can take weeks to produce. Continuous manufacturing consists of integrated unit operations with a continuous flow of material throughout. The bioreactor is perfused at a set rate and its effluent fed directly into the purification train, leading to periodic or continuous drug substance collection over a similar or extended time frame to meet product demands.

Developing Small-Scale Viral Clearance Models for Continuous Manufacturing

CDER researchers found three process steps to be key for promoting viral clearance during CM operations: capture chromatography, viral inactivation, and viral filtration. For these steps CM involves either a new technological change to the equipment (multicolumn chromatography) or an adaptation from an inherently static step to a dynamic step with extended processing times (continuous viral inactivation and filtration). Although the ICH Q5A guideline provides guidance on viral safety, it was developed with batch processing in mind. Thus, adapting ICH Q5A principles to developing small-scale studies on these integrated continuous process steps is needed. In an effort to provide scientific understanding, CDER labs investigated a commercially available continuous chromatography system and developed a potential representative small-scale model for continuous viral filtration.

A Model for Continuous Capture Chromatography

Continuous capture chromatography employs multiple smaller capture columns that can be overloaded, washed, or eluted simultaneously in a cyclical pattern. The overloading of the column and subsequent capture on a second column allows for >95% efficiency of resin use (compared to ~65% in a batch operation) and an overall reduction in processing time and resin cost; however, the overloading and additional columns, along with the additional flow paths and valves, could potentially impact the viral safety of the drug substance. CDER researchers, in collaboration with an equipment manufacturer, performed a side-by-side viral clearance comparison of a continuous capture chromatography step and a batch capture chromatography step (Chiang et al., 2019). The research found that although the initial cycle, or "start-up cycle," may affect variability in the log10 reduction value (LRV), the steady-state viral clearance capabilities were similar, with no difference seen between the columns within a cycle (Figure 2). Additionally, similar LRVs were observed between the continuous capture operation and the traditional batch mode operation, regardless of running conditions. These results suggest that there may be minimal impact to viral safety with the use of a multicolumn chromatography and that a simulated batch small-scale design is feasible with proper regulatory guidance.

Figure 2. Harvested cell culture fluid containing monoclonal antibody A was spiked with either bacteriophage PR772 or PhiX174 and the antibody was purified across a continuous protein A or batch protein A process step. The bar graphs show PR772 clearance (A) or PhiX174 clearance (B) when run in continuous mode under best case and worst case operating conditions. "1+1" means the flowthrough from one column is subsequently captured by a single column and not split to two columns. C) Overall log10 reduction value (LRV) value for the two viruses obtained from batch mode or continuous mode run in best and worst case conditions. See (Chiang et al., 2019).

Viral Filtration

In the case of continuous viral filtration, virus filters may be subject to three potential changes in operation: 1) extended processing times and/or volumes, 2) dynamic, or fluctuating, product fluid stream from the prior purification step, and 3) continuous flow instead of continuous pressure. Whereas there were some instances of virus filters being operated based on continuous flow, there were no developed models that could assess the ability to perform virus filtration over multiple days at low pressure or that mimicked the dynamic product fluid stream being loaded onto a filter. In collaboration with a filter manufacturer, CDER researchers used the well-characterized parvovirus surrogate, bacteriophage PP7, and selected human immunoglobulin as the protein to be purified, to successfully develop scale-down models to fill this need (Lute et al., 2020). Their extended process model was capable of operating virus filters for over 4 days without exceeding the recommended filter transmembrane pressure and with no loss in virus spike infectivity over the course of filtration time (Figure 3A). No virus was detected in the daily pooled effluent (>6 LRV), indicating effective viral clearance. A second model was able to successfully apply a dynamic load to the filter causing a gradient of increased protein concentration, buffer conductivity, and virus concentration. The results demonstrated that while there was an impact on filtration pressure with a dynamic fluid stream (Figure 3B), there was minimal impact on viral clearance, with observed increase in virus passage being related to total virus particles loaded and the filter being used. Although these studies were protein-, buffer-, and filter-specific, the models can be applied to other systems as a starting point to understand the impact of continuous processing on virus filtration.

Figure 3. Representative examples of continuous virus filtration models. A) An extended processing model showing application of a virus and protein load over 4 days and a throughput of 2900 L/m2. Blue and green traces are transmembrane pressure (TMP) for 2 separate runs. No virus was detected in any samples over the 4 days. B) Fluctuating load model showing a protein peak and virus being applied to a virus filter. The orange trace is the UV trace indicating that the protein concentration in the effluent matched the protein spike being applied. The blue trace shows TMP is impacted by the high protein spike and that pressure may not return to baseline. NOTE: LRV data LRV data from fluctuating load models: 2 runs with a Planova 20N filter (see B for traces) and 2 runs with a Planova BioEX filter, demonstrating that an increase in virus load led to virus passage for the 20N filter only. Sample names align with the dashed lines in B with spike samples being the 2mL fractions during the spike. Learn more.

Figure 3. Representative examples of continuous virus filtration models. A) An extended processing model showing application of a virus and protein load over 4 days and a throughput of 2900 L/m2. Blue and green traces are transmembrane pressure (TMP) for 2 separate runs. No virus was detected in any samples over the 4 days. B) Fluctuating load model showing a protein peak and virus being applied to a virus filter. The orange trace is the UV trace indicating that the protein concentration in the effluent matched the protein spike being applied. The blue trace shows TMP is impacted by the high protein spike and that pressure may not return to baseline. NOTE: LRV data LRV data from fluctuating load models: 2 runs with a Planova 20N filter (see B for traces) and 2 runs with a Planova BioEX filter, demonstrating that an increase in virus load led to virus passage for the 20N filter only. Sample names align with the dashed lines in B with spike samples being the 2mL fractions during the spike. Learn more.

How Does this Work Advance the Evaluation of Drugs and Biologics and Policy?

Continuous manufacturing is still a novel concept for therapeutic proteins, and there are few published studies dedicated to ensuring that such therapeutics are not contaminated due to viruses. Studies such as these provide both internal and external stakeholders with insights into understanding potential viral safety concerns and potential methods used for manufacturing developmental studies. As the submission of regulatory applications with continuous manufacturing elements increases, FDA subject matter expertise and tangible publicly available examples is critical for successful implementation of continuous manufacturing paradigms and is supportive of the Emerging Technology Program and other evaluations.

FDA Citations

Chiang, M-J, Pagkaliwangan, M, Lute, S, Bolton, G, Brorson, K, Schofield, M. Validation and optimization of viral clearance in a downstream continuous chromatography setting. Biotechnology and Bioengineering. 2019; 116: 2292– 2302. https://doi.org/10.1002/bit.27023

Lute, S, Kozaili, J, Johnson, S, Kobayashi, K, Strauss, D. Development of small-scale models to understand the impact of continuous downstream bioprocessing on integrated virus filtration. Biotechnol Progress. 2020; 36:e2962. https://doi.org/10.1002/btpr.2962

Source: https://www.fda.gov/drugs/regulatory-science-action/impact-continuous-manufacturing-processes-viral-safety-therapeutic-proteins

0 Response to "Adapting Viral Safety Assurance Strategies to Continuous Processing of Biological Products"

Postar um comentário